The Role of Room Sealing in Enhancing Air Quality Systems

At PureAir Filtration, we optimize air quality solutions for maximum efficiency and sustainability. Part of our process involves identifying and addressing potential problems before they occur. Room sealing is a process that we undertake in industrial settings to enhance the performance of our indoor air quality systems and to protect critical electronics from corrosion.

Why Room Sealing Matters

Simply put, a well-sealed room is more effective at keeping the good air in and the bad air out. However, achieving this isn’t as easy or straightforward as it sounds. Room sealing involves extensive planning and execution to ensure that all potential air leakages are addressed to create a complete barrier against particulate contamination.

While this process can add a level of complexity to a project, the benefits are worth the effort. Effective room sealing results in:

- LOWER capital costs for equipment

- MORE EFFICIENT equipment operations

- LOWER operating costs continuing for years following the installation

What is Involved in the Room Sealing Process?

- Defining the Space: The first step involves clearly defining the controlled space. This could be a single room or multiple rooms, attached or detached, each with its unique requirements and challenges.

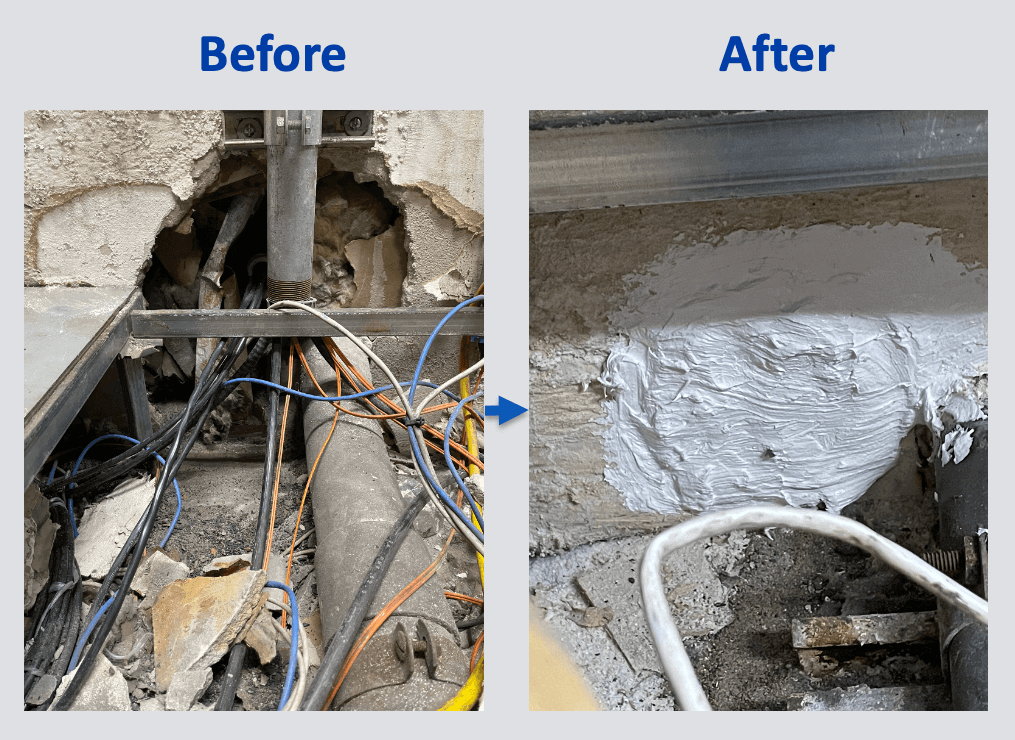

- Identifying Penetrations: The second step is to identify any possible openings, from obvious areas like open cable trays or holes in the walls to often overlooked areas like roof-wall seams, conduits, as well as light switches and outlets.

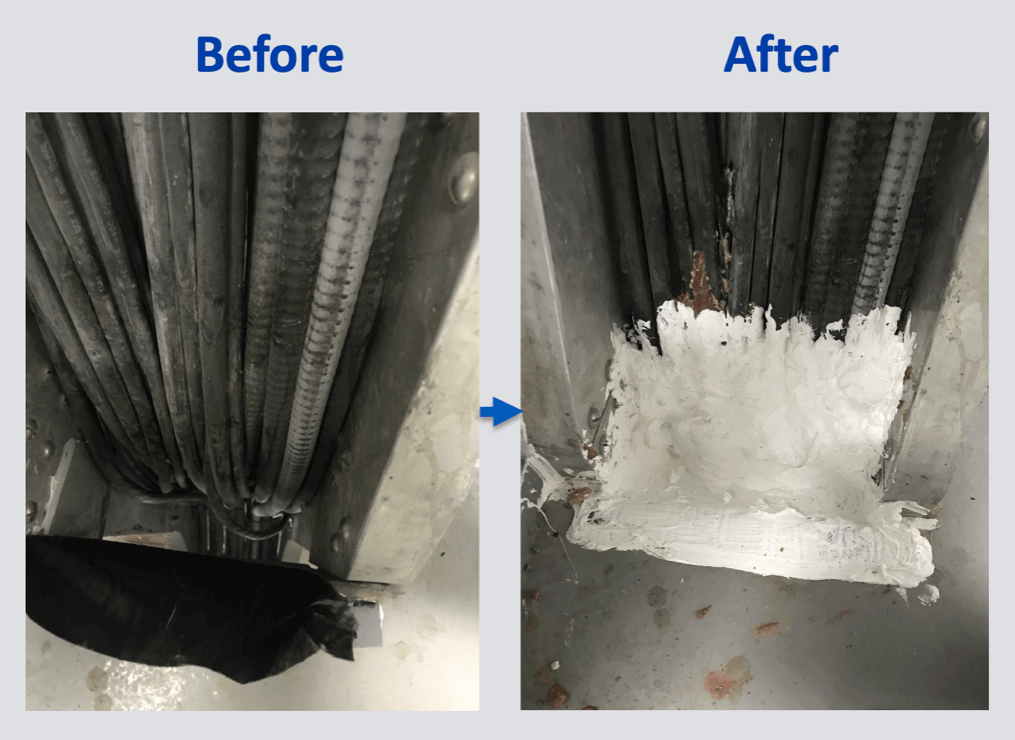

- Sealing: The third step in the sealing process is using materials such as fire-rated caulks and foams. Even the use of a simple coat of paint on porous block walls can act as an effective sealant.

- Testing Integrity: The fourth and final step is to perform a Room Integrity Test (RIT). This is done by using a blower door to measure if the sealed space meets the indoor air quality set standards. This test helps identify any missed spots and ensures the sealing’s effectiveness. With the final RIT information, equipment can be precisely sized for optimum performance instead of relying on generalized rules of thumb when upgrading the performance standards of the space.

Below are several before/after photos to illustrate the room sealing process.

PureAir’s Advanced Room Sealing Approach

What sets PureAir Filtration apart in the industry is its rigorous approach to the room sealing process. Unlike some competitors who may skip crucial steps like the Room Integrity Test (RIT), PureAir ensures that every potential air leakage point is accounted for and sealed. This meticulous process not only enhances the performance of the air purification system, but also significantly improves the overall air quality within the controlled environment.

Advanced Room Sealing Optimizes Efficiency

A well-sealed room means a smaller Air Purification Units (APUs) and subsequently a smaller Air Handling Unit (AHU) to condition the purified air will be needed. By reducing the number of units needed, companies can enjoy lower capital costs and more efficient operations. This translates into significant cost savings over time, making investment in the advanced room sealing process a wise decision for long-term operational sustainability.

The PureAir Filtration Commitment to Excellence

By adopting a thorough approach to indoor air quality, PureAir demonstrates its commitment to delivering comprehensive solutions. PureAir’s thorough process, combined with a deep understanding of the clients’ needs, ensures that industries ranging from paper mills to high-tech firms can maintain optimal indoor air quality standards crucial for their operations.

To discuss room sealing considerations at your facility, contact PureAir Filtration expert Steve Krpata.