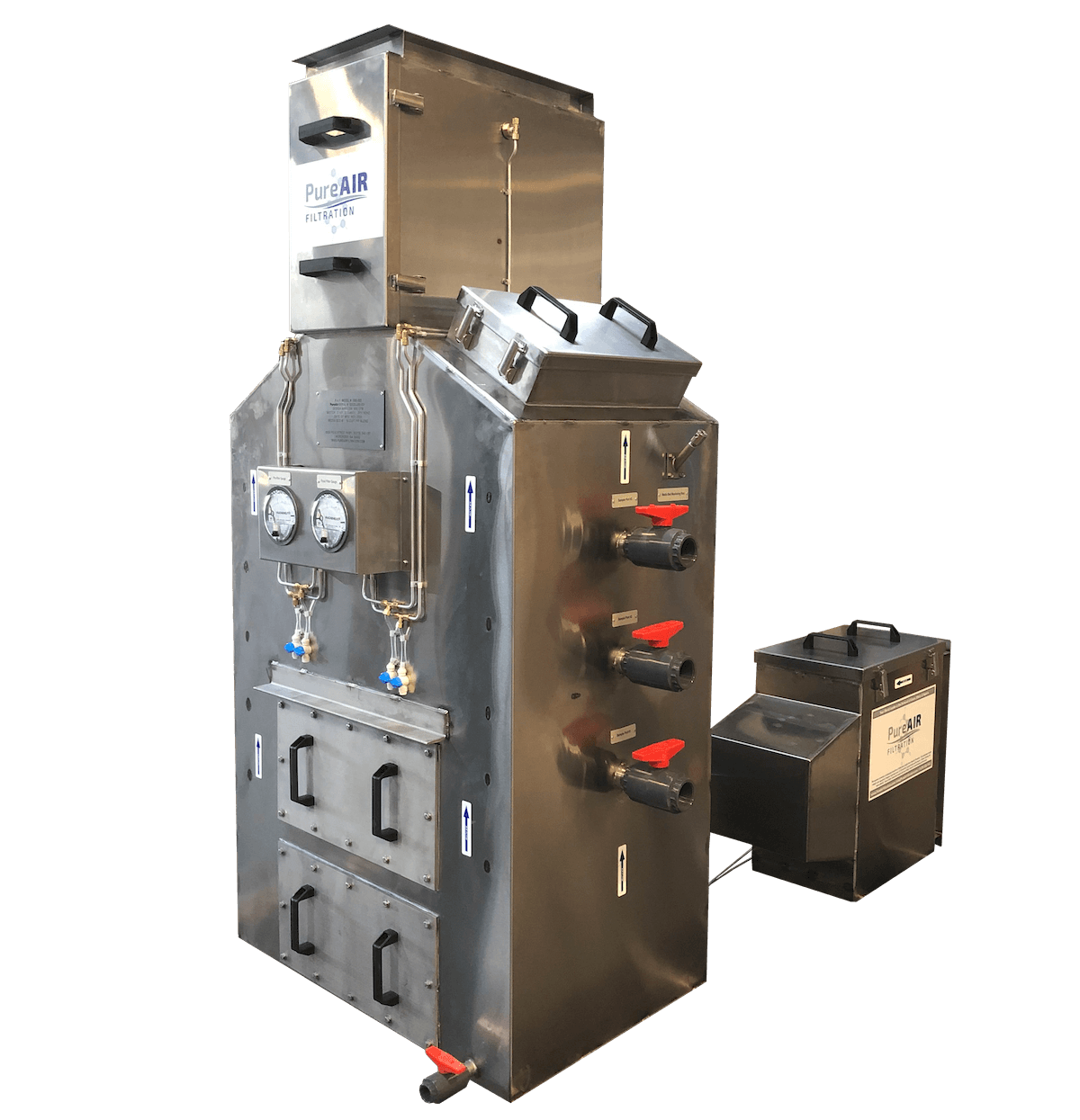

Industrial Vertical Bed System (I-VBS)

The PureAir® Industrial Vertical Bed System (I-VBS) is a vertical airflow system providing air purification for high contaminant levels.

This deep bed scrubber dispenses continuous high efficiency air purification for contaminated air streams ranging in volume from 300-5,600 CFM. Because the system has vertical airflow, the potential for air bypass is eliminated.

Used primarily in pulp and paper mills and other industrial facilities, it has the high airflow capacity needed to remove more than 99% of odorous and harmful corrosive gases.

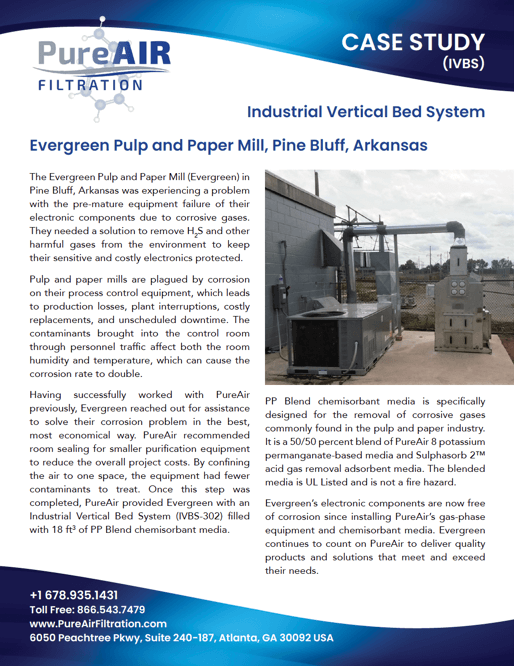

FACILITY TYPE: Evergreen Pulp and Paper Mill

LOCATION: Pine Bluff, Arkansas

EQUIPMENT/MEDIA USED: Industrial Vertical Bed System (I-VBS-302) filled with PP Blend chemisorbant media

PROBLEM: Pre-mature equipment failure of their electronic components due to corrosive gases.

SOLUTION: PureAir recommended room sealing for smaller purification equipment to reduce the overall project costs. Once this step was completed, PureAir provided Evergreen with an Industrial Vertical Bed System (I-VBS-302) filled with 18 ft3 of PP Blend chemisorbant media, which is designed to remove corrosive gases commonly found in the pulp and paper industry.

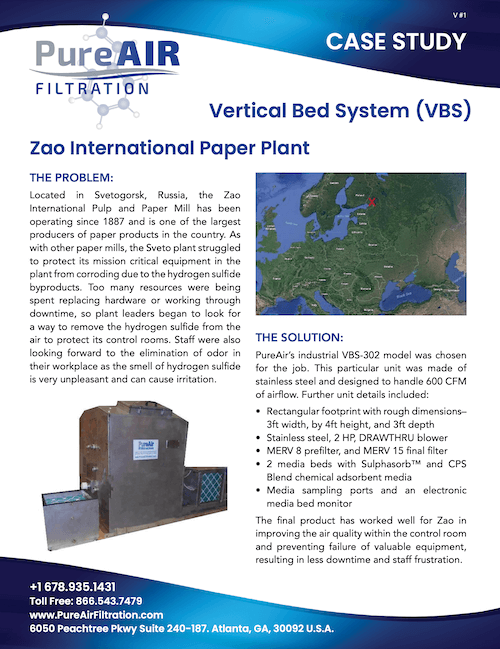

FACILITY TYPE: Zao International Paper Plant

LOCATION: Svetogorsk, Russia

EQUIPMENT/MEDIA USED: Vertical Bed System (VBS-302) filled with Sulphasorb™ media (no longer available) and CPS Blend adsorbent media, LIFEGARD™ media bed monitor

PROBLEM: Corrosive air is damaging mission critical electronic equipment in the plant and causing downtime and costly repairs.

SOLUTION: PureAir® installed a VBS-302 filled with both Sulphasorb™ media (no longer available) and CPS Blend adsorbent media to treat 600 CFM of malodorous air. They also installed an EBM to electronically monitor the media life and schedule changeout.