Emergency Gas Scrubber (EGS)

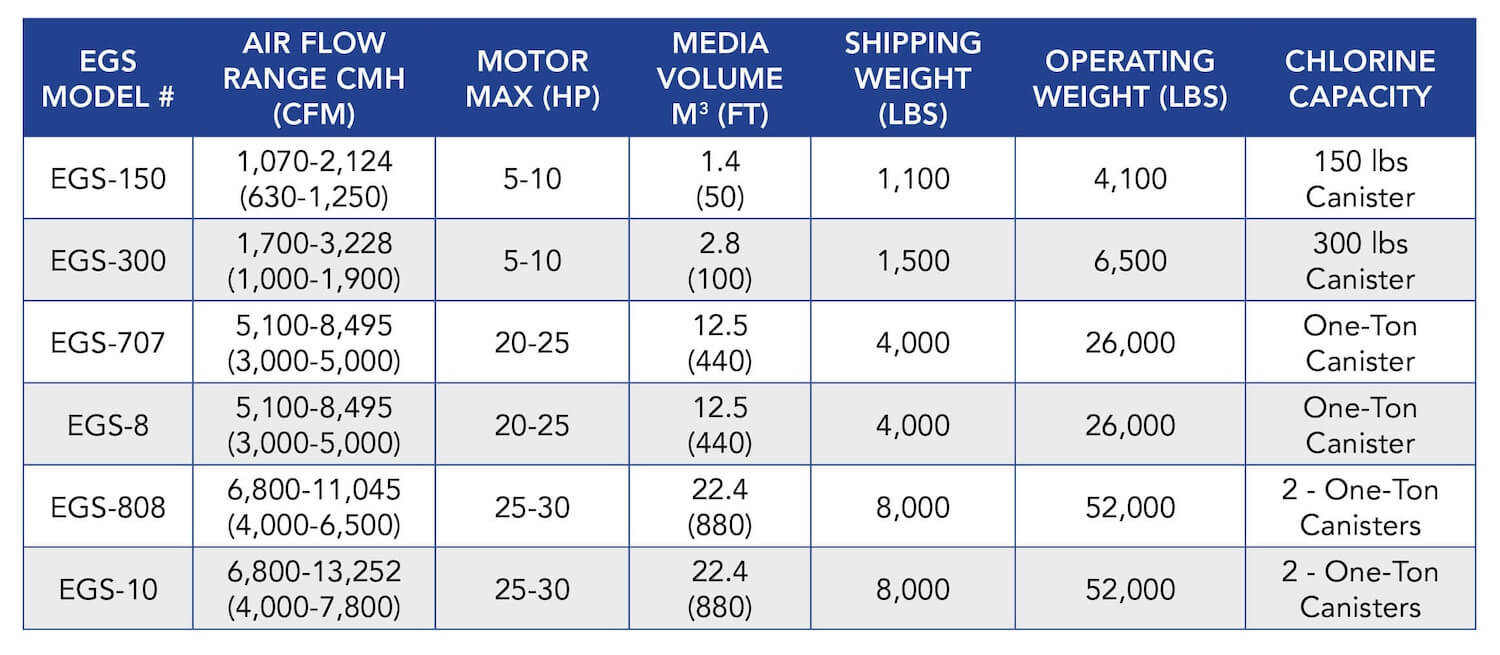

EGS-707

EGS-300

EGS-150

EGS-808

The Emergency Gas Dry Scrubber (EGS) from PureAir® is the best line of defense against hazardous chlorine leaks.

PureAir’s Emergency Gas Dry Scrubber (EGS) stands as the optimal defense against potential hazardous chlorine leaks. Distinguished by its single moving part, the EGS outperforms wet scrubber systems in terms of safety and reliability. Its reduced maintenance requirements, simplified operation, and lower cost further solidify its superiority. Utilizing Safetysorb chemisorbant media, an alumina-based, non-flammable, and UL Rated media, the EGS eliminates the risk of equipment damage in the event of a leak.

How does an EGS work?

In the event of a chlorine leak, the EGS swiftly activates, capturing the escaping gas and preventing potential harm to employees and citizens. This contrasts with outdated wet scrubbers that demand constant maintenance and handling of caustic solutions. The EGS, on the other hand, ensures safety, reliability, and freedom from costly maintenance.

PureAir’s EGS comes with a complimentary one-year warranty on materials, an affordable 10-year extended warranty, and free annual lab testing of its chemisorbant media. The installation process can be completed in as little as three days, and the systems can be customized to meet specific requirements including chlorine capacity removal.

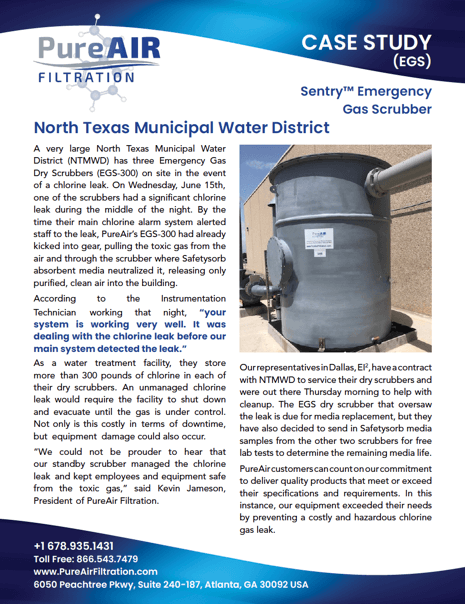

LOCATION: North Texas

EQUIPMENT/MEDIA USED: Emergency Gas Scrubber (EGS-300) and Safetysorb chemisorbant media

PROBLEM: The water treatment facility stores more than 300 pounds of chlorine onsite and needed a solution in the event of a leak

SOLUTION: PureAir’s EGS-300 kicked into gear when one of their dry scrubbers had a leak, pulling the toxic gas from the air and through the scrubber where Safetysorb chemisorbant media neutralized it, releasing only purified, clean air into the building. According to the Instrumentation Technician working the night of the leak, “your system is working very well. It was dealing with the chlorine leak before our main system detected the leak.”