Odor and Environmental Emission Control

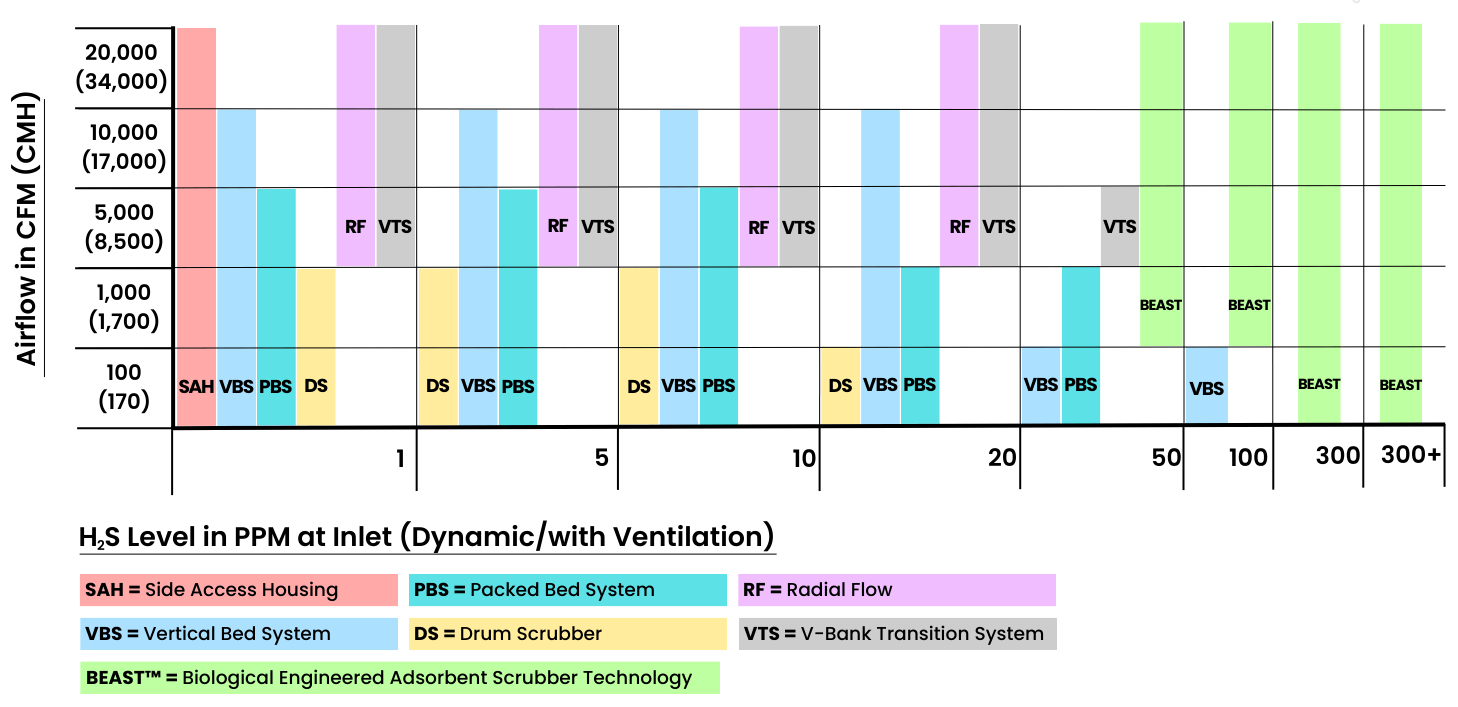

PureAir Filtration specially manufactures a number of products to remove unwanted odors and emissions from various environments, depending on the gas that is causing the problem.

Download Odor Control Solutions Brochure

PureAir Equipment for H2S Removal by Airflow

Wastewater Odor Control

PureAir is vastly experienced in Wastewater Odor Control, with many municipality customers from across the world.

We are able to provide custom systems to meet airflow, space requirements, and other customer needs and specifications.

H2S Removal

PureAir’s BEAST™ biological scrubber provides dependable hydrogen sulfide (H2S) removal to reduce corrosion, remove airborne gases from wastewater handling, food and beverage processing, and mining and tunneling operations.

FACILITY TYPE: Water Treatment Plant

LOCATION: Jackson, Mississippi

EQUIPMENT/MEDIA USED: Biologically Engineered Adsorbent Scrubber Technology Bioscrubber (BEAST™) and Sulphasorb Si™ media

PROBLEM: The process of dewatering digested biosolids at the water treatment facility releases H2S gas, which has a very distinct and unpleasant odor. The facility needed a solution to remove the odorous gas from the air and stop the odor complaints it was receiving from surrounding neighborhoods.

SOLUTION: PureAir determined the most efficient solution to remove the high volume of gases emitted at the facility is its BEAST™ (BST-2100) scrubber. This multi-stage scrubber is specifically designed for applications with very high H2S levels and offers fully remote monitoring capabilities. Since its installation, the BEAST™ scrubber has successfully removed 99.9% of H2S from the air and the odor complaints have stopped turning the customer into a good neighbor.

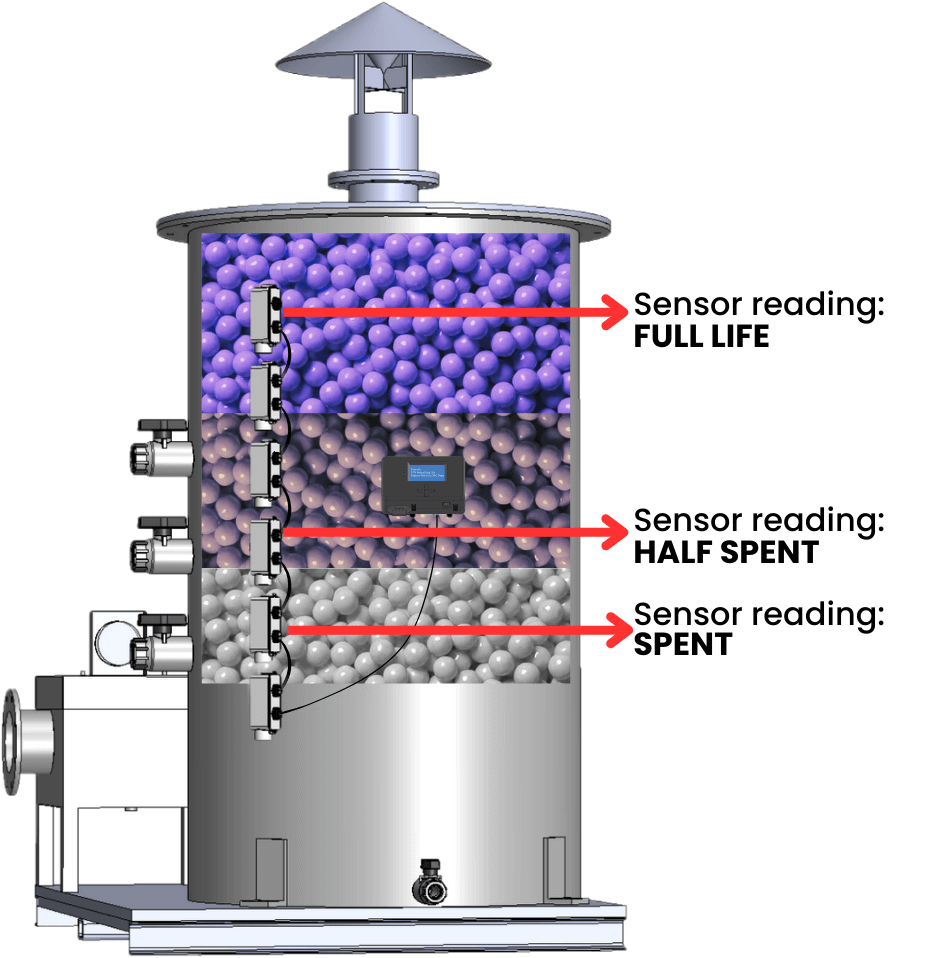

Air Quality Monitoring Tools

The Electronic Bed Monitor (EBMv2) is the only tool on the market that continuously monitors changes in media life in real time. Its electronic notification system alerts users when media is partially and completely consumed.

FACILITY TYPE: Robert O. Pickard Environmental Centre (ROPEC) – Wastewater Treatment PlantLOCATION: Ottawa, Canada

EQUIPMENT/MEDIA USED: 3 – V-Bank Transition (VTS) and Sulphasorb XL™ media, CPS Blend media, Ammoniasorb® media, and Omnisorb media, Electronic Bed Monitor (EBM)

PROBLEM: Remove H2S, Ammonia, and other VOCs released into the air during the water treatment process

SOLUTION: PureAir customized each VTS to have four beds of chemical adsorbent media rather than the standard two or three beds. To guarantee optimum and long-term system performance, which includes no escaping odors, ROPEC also decided to install an Electronic Bed Monitor (EBM) in each VTS. EBM’s measure the remaining life of the adsorbent media in real time to ensure there is no breakthrough.

Other Industrial and Commercial Odor Control Applications

PureAir is experienced in removing odors at a number of other commercial and industrial applications, and our custom designed units and high quality media can fit various space requirements, while removing all odorous gases.

Food and Beverage Processing Facilities:

Dairy processing facilities, breweries, and other food and beverage processing facilities often produce strong odors that our systems can remove to keep customers, employees, and neighbors happy.

FACILITY TYPE: Dannon Yogurt Plant

LOCATION: Ohio

EQUIPMENT/MEDIA USED: Vertical Bed System (VBS) filled with Sulphasorb XL™ media, CPS12 Blend media, and Omnisorb media

PROBLEM: Eliminate odor complaints from surrounding neighbors created by their wastewater plant that manages the cream waste by-product used to make Greek Yogurt.

SOLUTION: PureAir installed a VBS after the underperforming biofilter that was only removing 90% of the H2S and none of the other odors. Three chemisorbant media were used to remove H2S, Methyl Mercaptan, and Dimethyl Disulfide. Since installation, Dannon reported that all odors were removed, and customer complaints were eliminated.

–Kevin Bock, Dannon Yogurt

Cannabis:

PureAir Cannabis grow facilities often emit an unwanted odor, and our chemisorbent media is perfect for removing the terpenes in cannabis that cause these unpleasant odors.

Tourist Locations & Attractions:

Many high traffic areas such as hotels, resorts, and other tourist attractions rely on PureAir’s systems to remove odors that can bother customers.

Pharmaceutical & Chemical Manufacturing:

Our systems help pharmaceutical and other chemical manufacturing companies to meet regulatory standards for emission and odor control.