Vertical Bed System (VBS)

PureAir® Vertical Bed System (VBS) system is a complete self contained, vertical airflow unit.

This deep bed system provides continuous high efficiency air purification for contaminated air streams ranging in volume from 160 to 16,960 CFM.

Because the system has a vertical airflow, the potential for air bypass is eliminated. The VBS system is available in either blow-through or draw-through configurations.

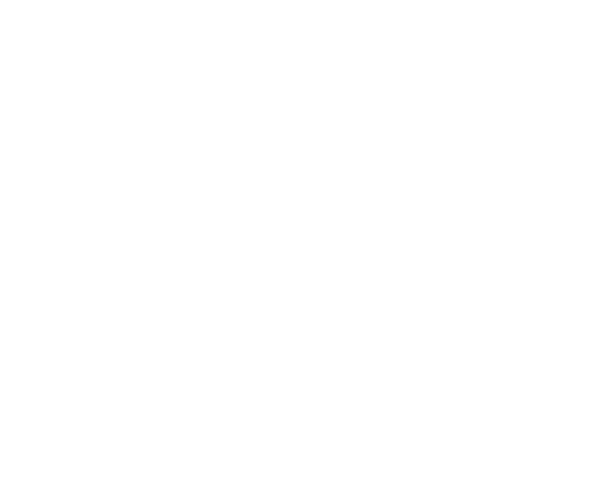

FACILITY TYPE: Georgia Pacific Paper Mill

LOCATION: Crossett, Arkansas

EQUIPMENT/MEDIA USED: Vertical Bed System (VBS) and Sulphasorb XL™ chemisorbant media

PROBLEM: Corrosive air is damaging mission critical electronics and malodorous odors is affecting conditions for the staff

SOLUTION: PureAir® installed a VBS filled with Sulphasorb XL™ chemisorbant media to remove odors and protect critical electronics.

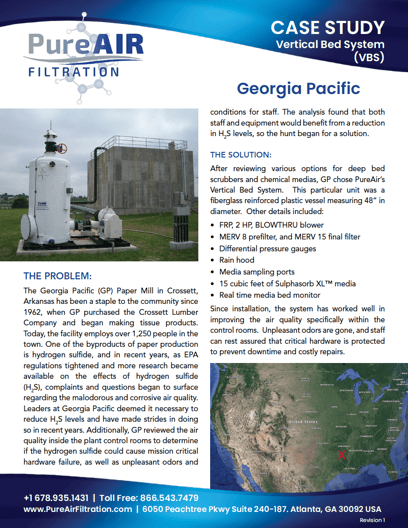

FACILITY TYPE: Chisholm Creek Water Treatment Plant

LOCATION: Oklahoma City, Oklahoma

EQUIPMENT/MEDIA USED: Dual Train System – VBS-720 roughing air scrubber with Sulphasorb FeXL™ chemisorbant media and VBS-720 polishing air scrubber with Sulphasorb XL™ chemisorbant media

PROBLEM: Chisholm Creek needed an odor solution for their extremely elevated levels of H2S and other sulfur compounds released during sewage processing that was cost effective and not high maintenance like chemical or wet scrubbers.

SOLUTION: PureAir® recommended using a Dual Train VBS-720 system. The VBS-720 is a limited maintenance system designed to manage a high volume of airflow with a considerable saturation of H2S. PureAir® recommended using Sulphasorb FeXL™ blended chemisorbant media because it can remove 45% of its weight in H2S, making it an all-around more effective choice than carbon. It is a 50/50 blend of Sulphasorb XL™ chemisorbant media and Sulphasorb Fe™ chemisorbant media. Sulphasorb FeXL™ chemisorbant media is used as a roughing filter for cost effective and complete odor removal.