Toxic Gas Scrubber Equipment

Toxic Gas Mitigation Systems

Depending on the amount of toxic gas that is stored or used onsite, a toxic gas scrubber may be a requirement. In cases where a toxic gas scrubber is not in place, a leak situation would mean that the facility has to shut down and evacuate until the gas is under control. Not only is this costly in terms of downtime, but equipment damage could occur, or worse yet, employee illness or hospitalization may be required. An effective and reliable standby scrubber can mitigate this risk.

The Risk Management Plan (RMP) Rule

Section 112(r) of the 1990 Clean Air Act amendments requires implementation of a Risk Management Plan (RMP) Rule. The RMP rule requires facilities that use extremely hazardous substances to develop a formal Risk Management Plan. These plans must be revised and resubmitted to EPA every five years. Customers can make great improvements to their EPA Risk Management Plan (RPM) by installing a PureAir Sentry™ scrubber.

Sentry™ Emergency Gas Dry Scrubber

PureAir Sentry™ Emergency Gas Dry Scrubber is the best line of defense against hazardous chlorine gas leaks at water treatment facilities. Only one moving part means the Sentry™ is safer and more reliable than conventional wet scrubber systems because it needs less maintenance, is easier to operate, and costs less.

PureAir Sentry™ with Safetysorb chemisorbant media is alumina-based so it is fireproof, earning it a UL Rating. Not only does this system guard against leaks, it can improve EPA Risk Management Ratings.

The Emergency Toxic Gas Scrubber Solution

PureAir Sentry™ is ideal for industrial facilities storing chlorine or ammonia, municipal and industrial water treatment, water pump stations, pulp and paper mills, and chemical manufacturers.

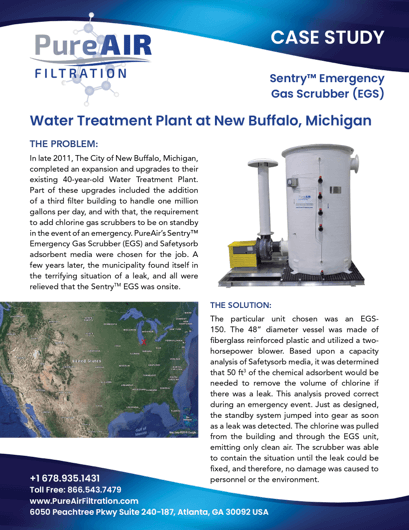

EQUIPMENT/MEDIA USED: Emergency Gas Scrubber (EGS-150) and Safetysorb chemisorbant media

PROBLEM: The water treatment facility added a third filter building to handle the one million gallons of chlorine used per day and needed a standby gas scrubber in the event of an emergency.

SOLUTION: PureAir® emergency gas scrubber (EGS-150) made of fiberglass reinforced plastic and filled with Safetysorb chemisorbant media was chosen to handle the high volume of chlorine if there was a leak. Just as designed, the standby system jumped into gear during a chlorine leak and was able to contain the situation until the leak could be fixed, keeping personnel and the surrounding area free from harm.