Advanced Protection for Critical Electronics

PureAir® specializes in protecting sensitive electronic equipment from the harmful effects of corrosive gases. PureAir’s custom solutions are engineered to safeguard mission-critical electronics in high-risk environments—ensuring reliability, safety, and operational continuity.

Why Corrosion Control Matters

Corrosive gases such as hydrogen sulfide and sulfur dioxide can lead to whisker growth and short-circuiting in electronic components. These failures can cause costly equipment damage, unexpected production loss, plant shutdowns, and even safety incidents.

Serving High-Stakes Industries

PureAir serves a wide range of industries where air quality is crucial:

- Data Centers and Control Rooms – Super-purified air protects valuable servers, preserving data integrity and saving repair costs

- Oil & Gas Refineries and Motor Control Centers – PureAir’s systems eliminate corrosive emissions in command centers and electronic enclosures, preventing corrosion-related failures

- Manufacturing Facilities & Process Plants – Maintain everyday operations and protect critical infrastructure.

Scalable, High-Performance Air Handling Solutions

PureAir offers varied models of air handling units to meet and exceed specific needs:

- Customizable Units – Engineered to meet unique air quality demands and application specs.

- Turnkey Units – Compact and portable options like the PFU-Mobile and PFU-Mini are available for rapid startup.

- High-Capacity Packaged Filter Units (PFUs) – Larger units designed for areas with greater airflow and higher contaminant levels.

- Side Access Housing (SAH) Units – Ideal for applications requiring robust, highly customized filtration performance.

- Deep Bed Systems – Deliver long-lasting service life and enhanced protection in the harshest environments.

Protect What Matters Most

From data centers to oil and gas refineries, PureAir delivers clean air solutions that protect electronics, reduce downtime, and support uninterrupted operations.

Get in touch today to learn more about PureAir’s systems.

Download Protecting Electronic Assets Brochure

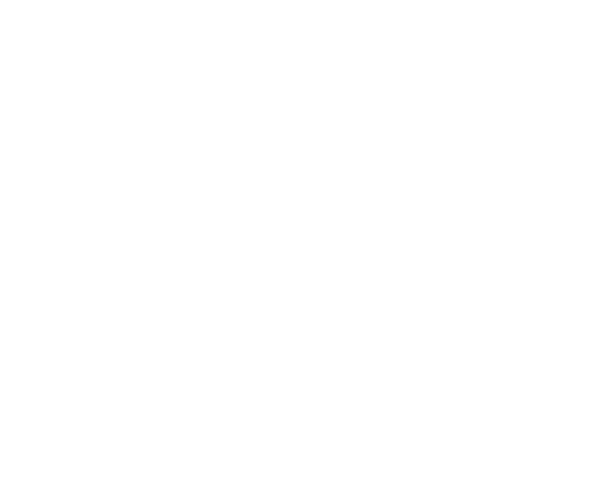

FACILITY TYPE: Progroup PM3 PapermillLOCATION: Leipzig, Germany

EQUIPMENT/MEDIA USED: Side Access Housing units (SAH), PurePak 12 modules, Sulphasorb™ media (no longer available) and PureAir 8 chemisorbant media

PROBLEM: Remove hydrogen sulfide (H2S), sulfur dioxide (SO2), and sulfite (SO3), and other corrosive gases that could cause damage to mission critical electronics and data systems in control rooms.

SOLUTION: PureAir® provided Side Access Housing (SAH) units with PurePak-12 modules filled with Sulphasorb™ media (no longer available) and PureAir 8 media. The systems and media reduced corrosive gas levels and maintained those levels at G1 air quality in the control rooms.

Looking to monitor corrosive gas environment levels?

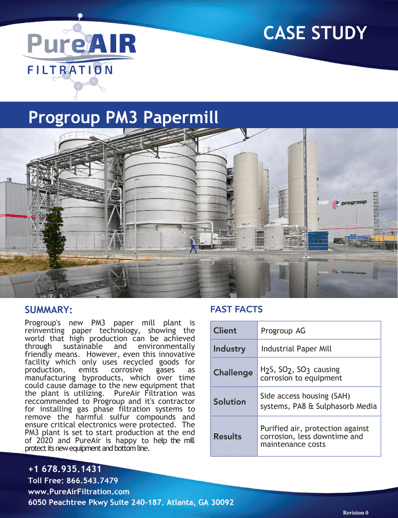

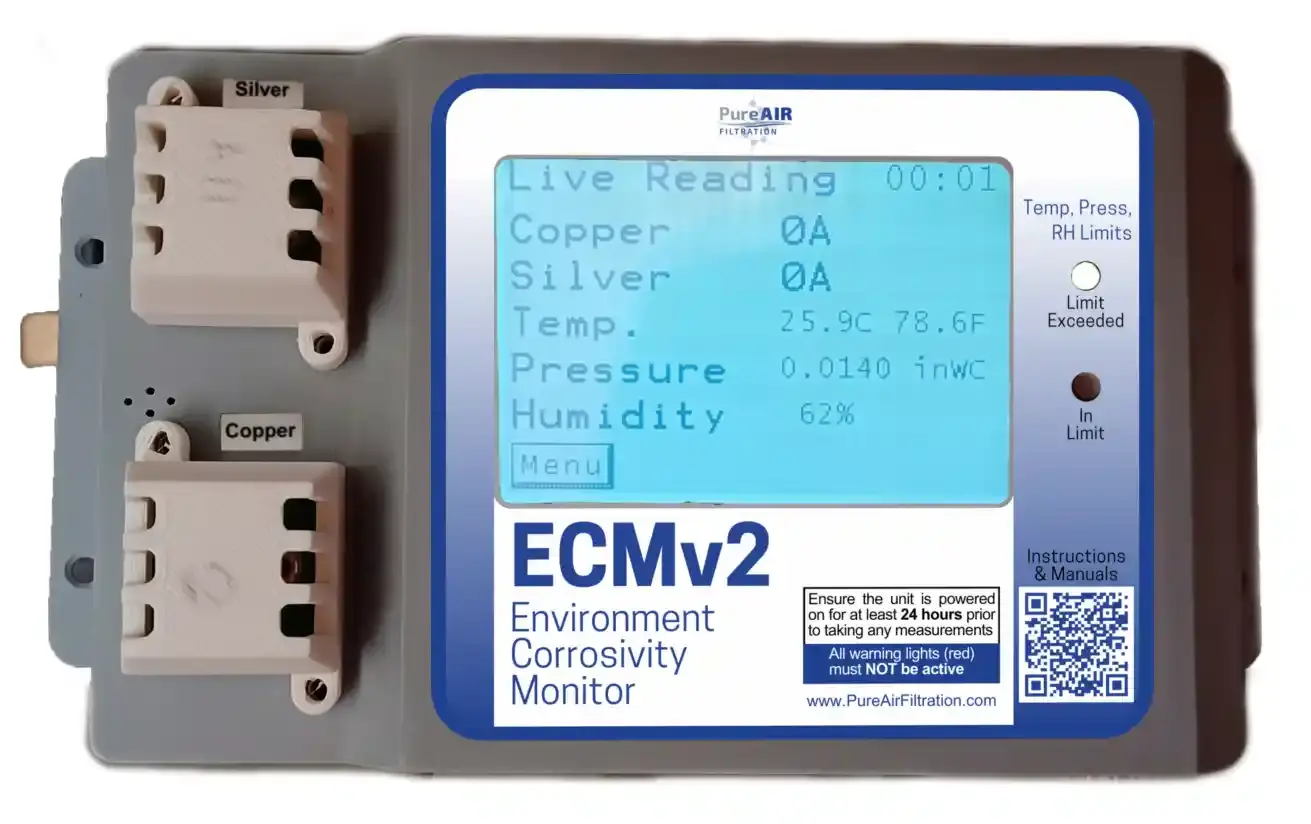

PureAir ECMv2:

- Delivers live critical air quality data to accurately determine which corrosive gases are present and at what levels.

- This monitor protects equipment, extends its lifespan, and anticipates costly downtime events.

Benefits:

- Constant Environment Surveillance

- Early Corrosion Detection

- Easy to Install

- Long Service Life

- Connects to varied systems for data capture

- SD Card for data storage

ISA Standards

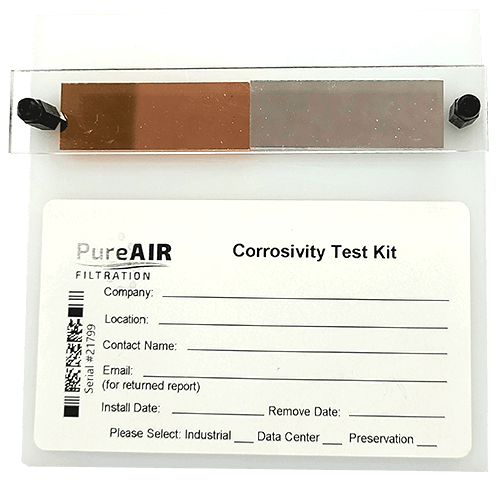

Worldwide Standard for Protecting Industrial Electronics: ISA S71.04

- G1 level needed to protect electronics, but many factors must also be considered:

- Configuration, air recirculation vs pressurization

- Air tightness of the area

- Contamination brought into the room with traffic

- Air tightness of the ducts

- Room walls in contact with corrosive air

- Relative humidity < 50%

- Temperature target 22°C and stable

| ISA CLASSIFICATION | ||||

|---|---|---|---|---|

| G1 | G2 | G3 | GX | |

| Mild (Acceptable) | Moderate | Harsh | Severe | |

| Corrosion is not a factor | Corrosion is measurable | High probability that corrosion attacks will occur | Electronic/electrical equipment is not expected to survive | |

| Copper Reactivity Level | 0-299 Angstroms | 300-999 Angstroms | 1000-1999 Angstroms | ≥ 2000 Angstroms |

| Silver Reactivity Level | 0-199 Angstroms | 200-999 Angstroms | 1000-1999 Angstroms | ≥ 2000 Angstroms |

| Contaminants | Concentration | |||

| H2S Hydrogen Sulfide | < 3 ppb | < 10 ppb | < 50 ppb | ≥ 50 ppb |

| SO2 Sulfur Dioxide | < 10 ppb | < 100 ppb | < 300 ppb | ≥ 300 ppb |

| CL2 Chlorine | < 1 ppb | < 2 ppb | < 10 ppb | ≥ 10 ppb |

| NOx Nitrogen Oxides | < 50 ppb | < 125 ppb | < 1250 ppb | ≥ 1250 ppb |

| NH3 Amonia | < 500 ppb | < 10,000 ppb | < 25,000 ppb | ≥ 25,000 ppb |

| O3 Ozone | < 2 ppb | < 25 ppb | < 100 ppb | ≥ 100 ppb |

| HF Hydrogen Fluoride | < 1 ppb | < 2 ppb | < 10 ppb | > 10 ppb |