Chlorine Gas Leak Solution

Why Chlorine Gas Leaks Present a Hazard

Chlorine gas is considered toxic. Ammonia-like in odor, chlorine gas is irritating to both the eyes and throat, and can cause difficulty in breathing. When liquid chlorine turns into a gas it is highly flammable. If ignited, the smoke resulting from a chlorine fire can pose serious health and safety risks to the surrounding area.

Since chlorine gas is toxic, a leak involving chlorine gas should be considered a hazardous situation. A dry scrubber system should be in place to mitigate the risks.

Emergency Gas Dry Scrubber for Chlorine Gas Leaks

PureAir Sentry™ Emergency Gas Dry Scrubber provides a dependable line of defense against hazardous chlorine gas leaks. As a highly effective toxic gas scrubber, it is widely used at water treatment facilities, water reclamation operations, paper mills, chemical manufacturers, and similar types of industrial sites.

The Sentry™ has only one moving part so it needs less maintenance, is easier to operate, costs less, and is safer and more reliable than conventional wet scrubber systems. This scrubber uses PureAir® Safetysorb absorbent media, which is alumina-based and fireproof, earning it UL Rating. Not only does this system guard against leaks, it improves your EPA Risk Management Rating.

Manage Chlorine Gas Leak Risks

PureAir Sentry™ is the effective and dependable choice for promoting safety at industrial facilities storing chlorine or ammonia, municipal and industrial water treatment, water pump stations, pulp and paper mills, and chemical manufacturers.

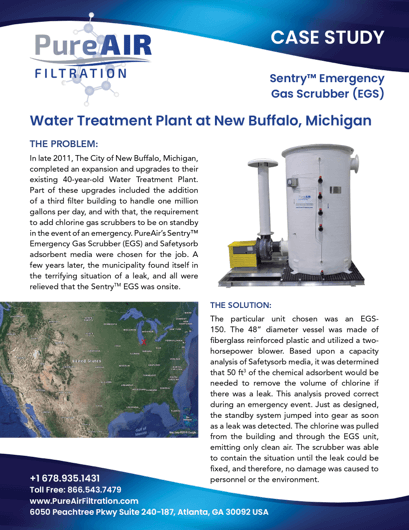

LOCATION: New Buffalo, Michigan

EQUIPMENT/MEDIA USED: Emergency Gas Scrubber (EGS-150) and Safetysorb adsorbent media

PROBLEM: The water treatment facility added a third filter building to handle the one million gallons of chlorine used per day and needed a standby gas scrubber in the event of an emergency.

SOLUTION: PureAir® emergency gas scrubber (EGS-150) made of fiberglass reinforced plastic and filled with Safetysorb adsorbent media was chosen to handle the high volume of chlorine if there was a leak. Just as designed, the standby system jumped into gear during a chlorine leak and was able to contain the situation until the leak could be fixed, keeping personnel and the surrounding area free from harm.